Advantages

High precision, high speed

No friction, no noise

Compact structure, safe and reliable

High performance, long life

Excellent quality, stable operation

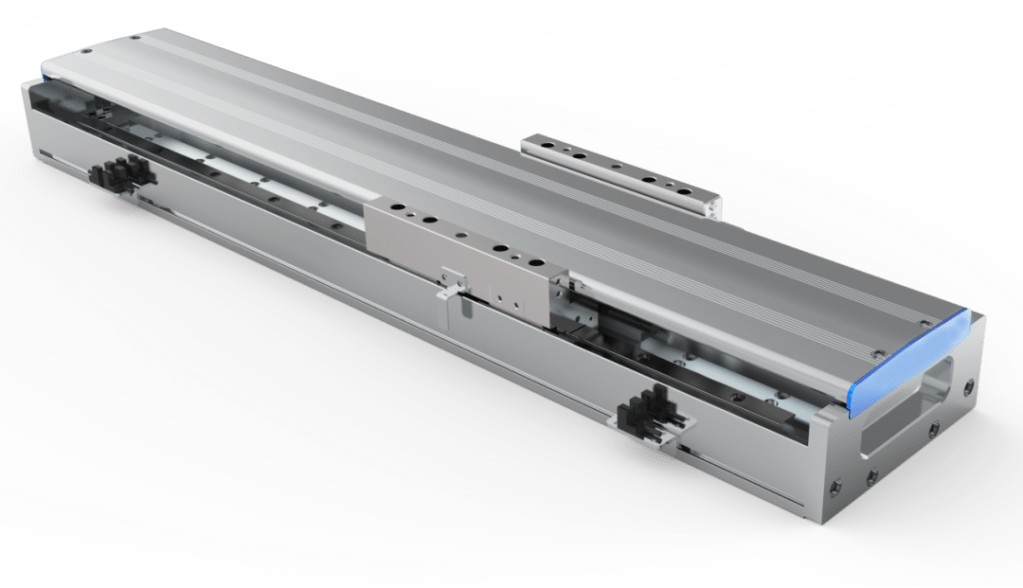

DDL Direct Drive Linear Motor

- Simple structure

The additional device for converting rotary motion into linear motion is eliminated, and the weight and volume are greatly reduced.

- High positioning accuracy

Linear motors can achieve direct transmission, eliminating various positioning errors caused by intermediate links, so the positioning accuracy is high.

- Safe, reliable and long life

Linear motors can achieve contactless transmission of force, and the mechanical friction loss is almost zero, so there are fewer failures and maintenance-free, so the work is safe, reliable and long life.

- No wear or maintenance-free

Linear motors have fewer parts, and do not require nuts, bearing seats, couplings, motor bases and other ball screw parts, nor do they need to maintain such parts. Therefore, the service life is extremely long, the operation is clean, and there is no need to lubricate or maintain such parts.

- Unlimited stroke

The stroke of the linear motor can be unlimited by splicing the stator, and multiple independent motion controls in the same axis can also be achieved by configuring multiple movers on the same stator.

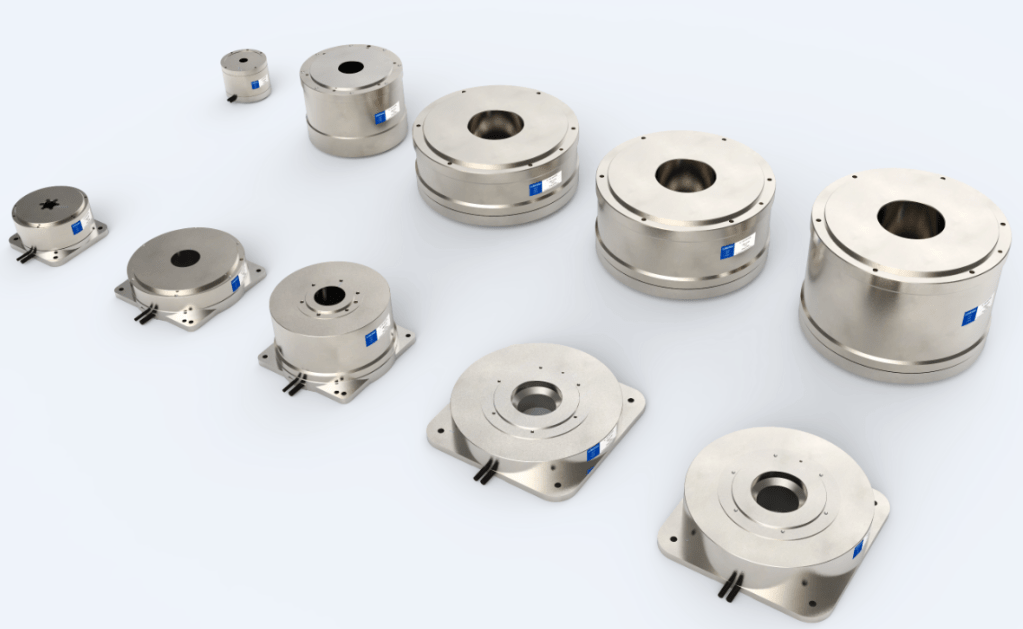

DDR Direct Drive Rotary MotorsNo wear or maintenance-free

DDR motor is a torque motor that directly drives the load without any transmission components. DDR motors are compact and rigid. They generate high torque by using high-energy permanent magnets. At the same time, the built-in optical encoder gives the system better positioning accuracy and higher dynamic response. The use of high-rigidity cross roller bearings improves the mechanical characteristics of the system.

Core Advantages

Simple and compact structure, no need to add transmission mechanism;

High reliability, high dynamic response;

High rigidity, can withstand load fluctuations;

High efficiency;

High positioning accuracy;

Easy to install, frictionless, maintenance-free

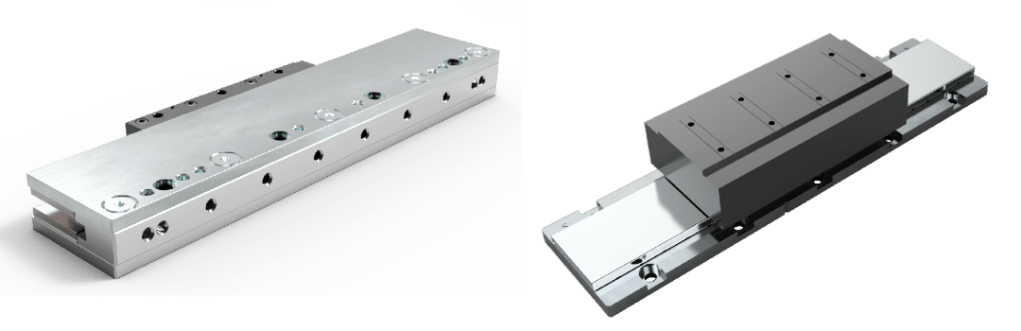

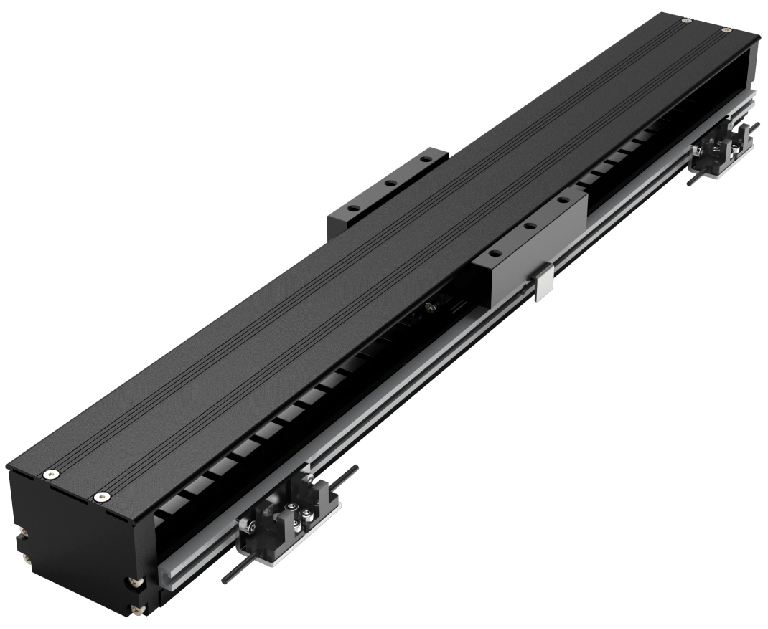

Single axis module

The linear motor module uses the independently developed linear motor and the application of non-contact direct drive transmission technology, which enables precision machining and precision measurement equipment to have reliable, stable, accurate and fast positioning capabilities; the standardized and modular design makes large-scale batch production possible.Direct drive transmission technology has the characteristics of high dynamic characteristics, high speed, high precision, etc.; unique structural design, ultra-high thrust density, better performance and smaller size.

KPS embedded direct drive module

Micron-level walking parallelism, low Z-axis runout; Fully closed-loop control, high precision;

A/B movers can be mixed and matched, and independently controlled;

The motor is embedded in the body, no adapter flange & servo motor is required;

Good bidirectional repeatability, no screw backlash error.

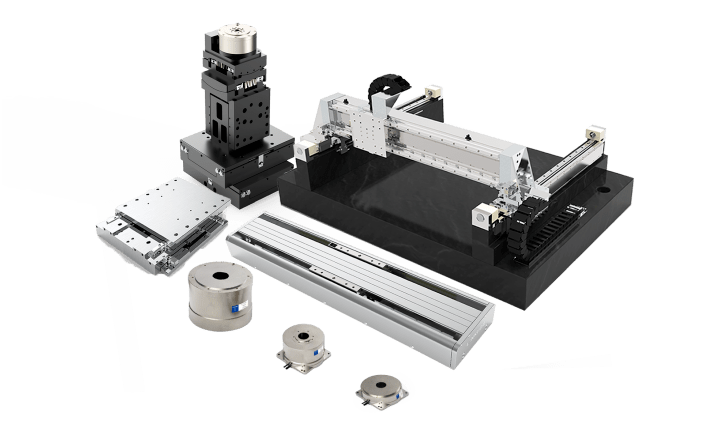

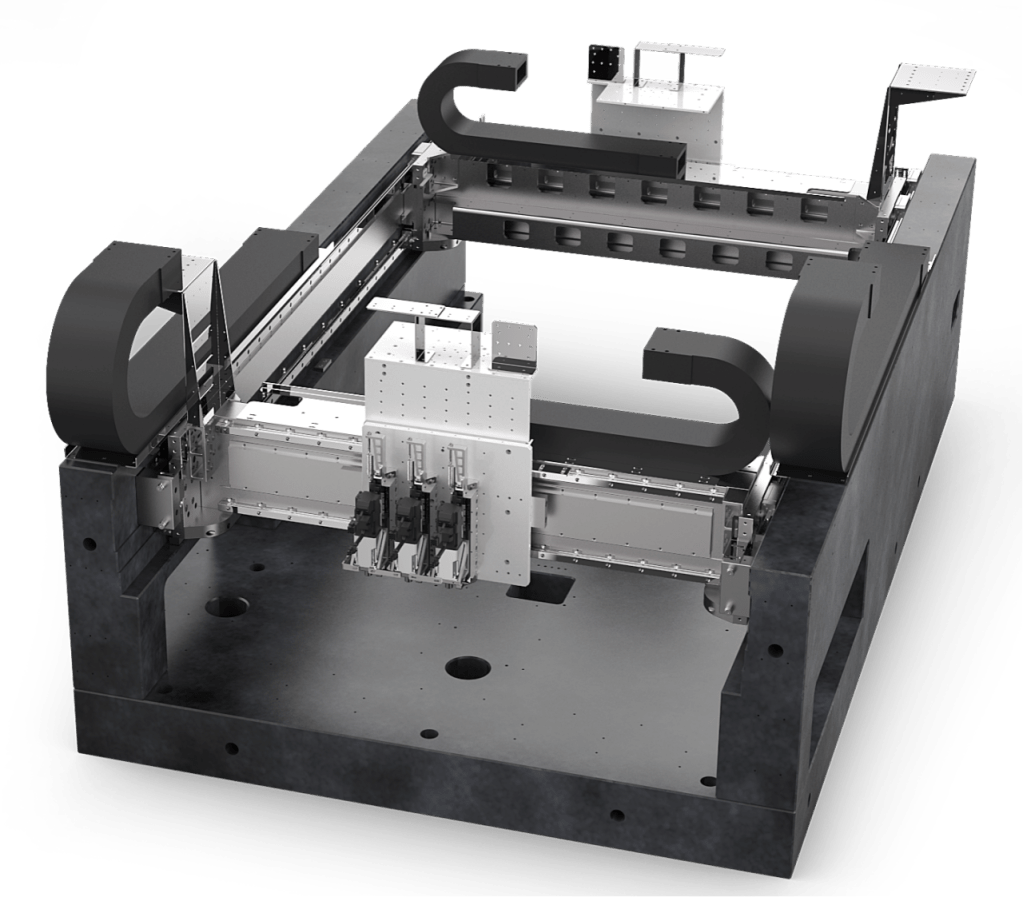

Gantry Dual Drive Linear Motor Platform

High speed

Use high-thrust iron core linear motor, the maximum speed can reach 2.5 m/s.

High precision

Bilateral grating position feedback, real-time position adjustment, easy to achieve high-precision positioning.

Large stroke

Add flexible adjustment mechanism, reduce the influence of gantry axis installation error, easy to achieve large stroke movement.

Modular multi-degree-of-freedom adjustment platform

All the motion axes of the multi-degree-of-freedom adjustment platform are powered by direct-drive motors, which can complete fast and high-precision adjustment of lines and angles; at the same time, the modular and integrated design of the product can achieve free combination and precise alignment.

High thrust density linear motor, integrated design, large load capacity;

Achieve small step motion, fast adjustment, and precise positioning;

Low speed fluctuation, achieving high precision in the motion process.